Hydraulic Cylinder End Cap Design

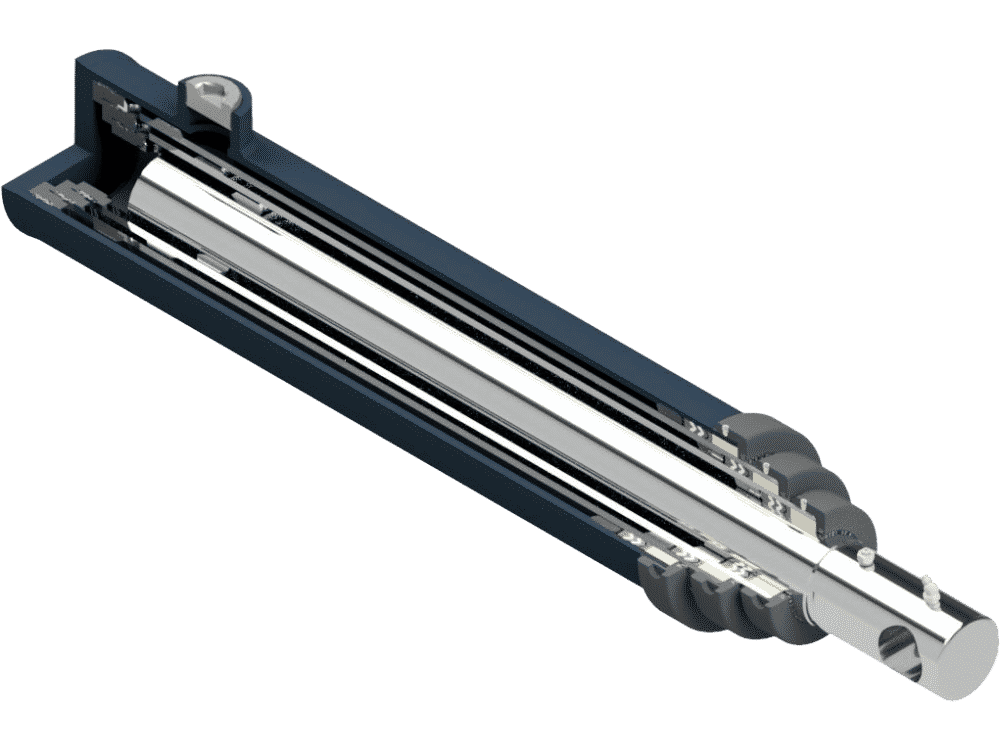

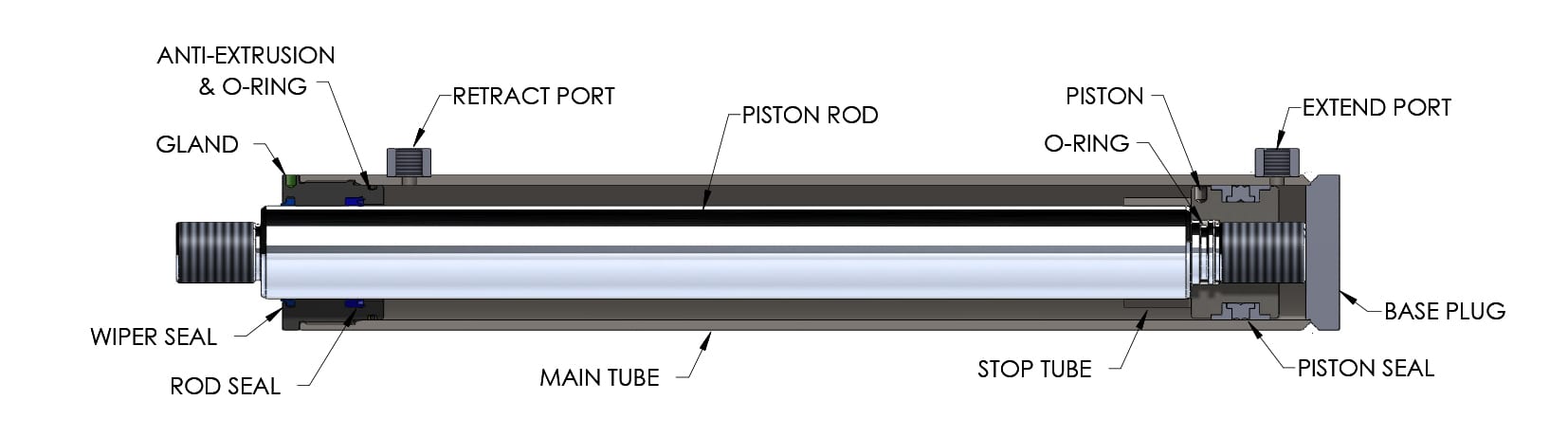

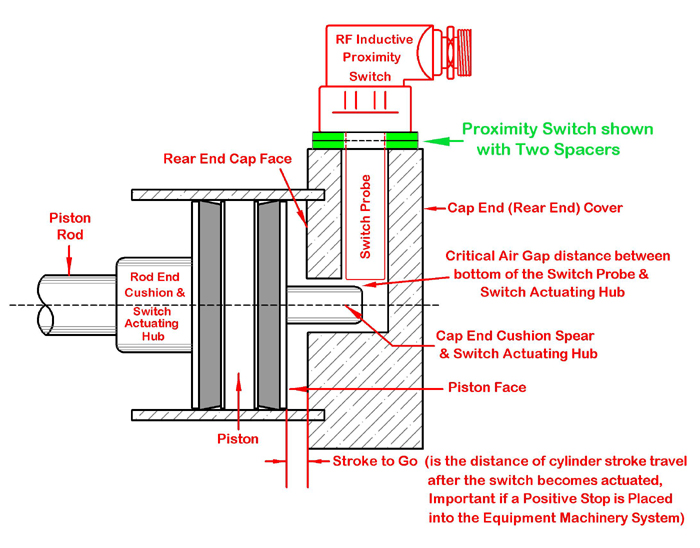

The barrel is closed on one end by the cylinder bottom also called the cap and the other end by the cylinder head also called the gland where the piston rod comes out.

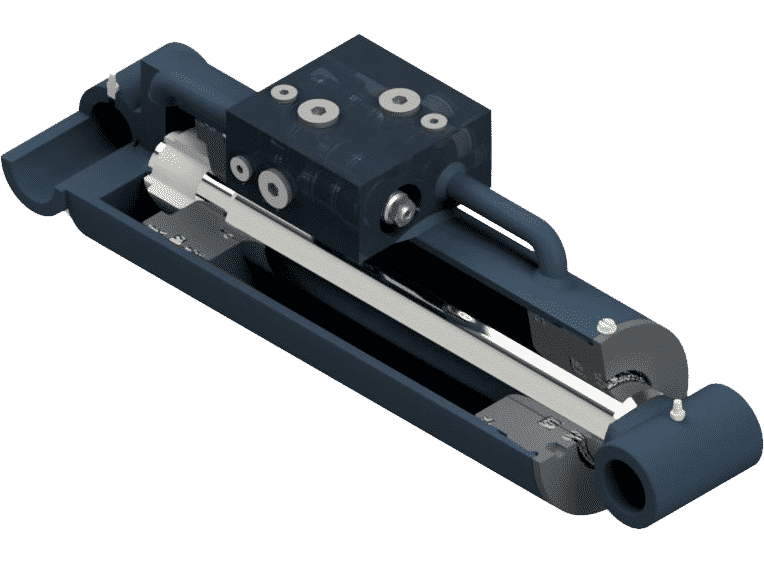

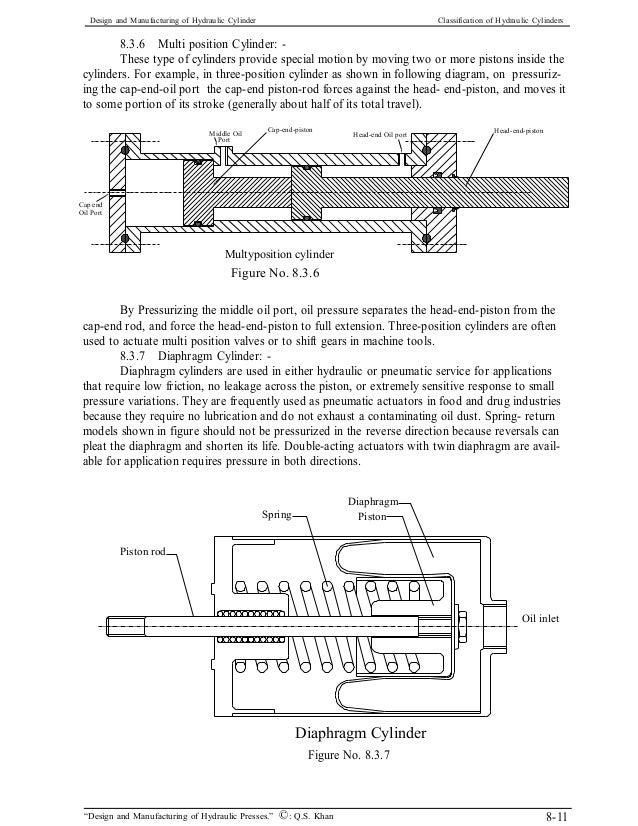

Hydraulic cylinder end cap design. Custom hydraulic cylinder design and manufacturing. Double acting cylinders have ports at both cap and rod ends. Custom welded rod cylinders. These modifications allow disassembling the cylinder for repair but also raise its initial cost.

The cylinder is extended by pumping hydraulic fluid into the cap end of the cylinder which moves the piston and rod. Custom welded rod cylinders. Custom telescopic hydraulic cylinders. The outside diameter of the cylinder end cap was 4 25 in and the inside diameter of the cylinder is 3 5 in.

Fluid in the rod end of the cylinder is exhausted out of the rod end port. Custom telescopic hydraulic cylinders. End caps hydraulic cylinder component parts standard duty 33 00 329 00. The barrel is closed on each end by the cylinder bottom also called the cap end and by the cylinder head where the piston rod comes out of the cylinder.

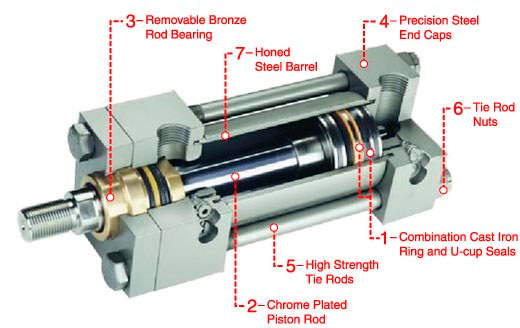

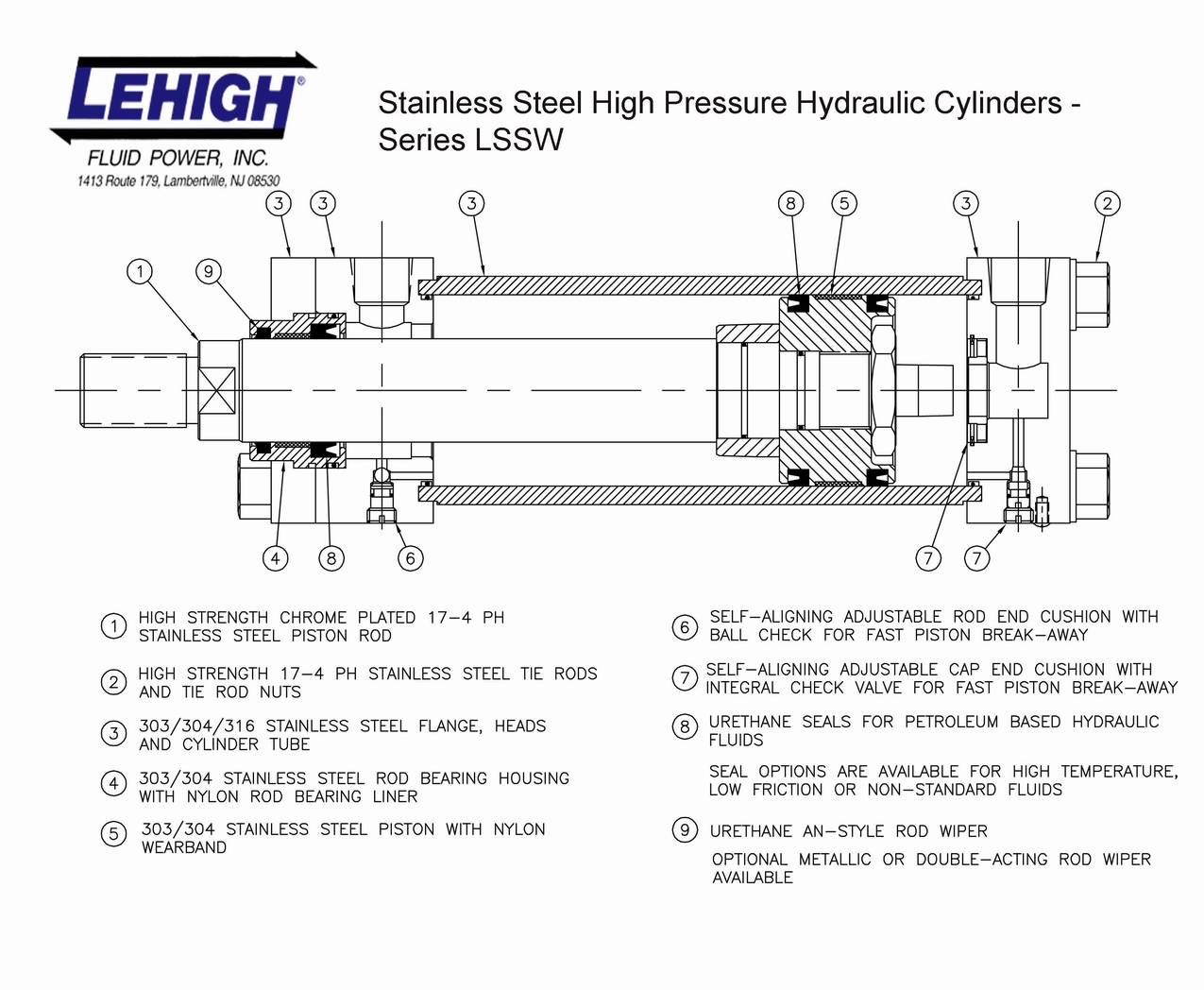

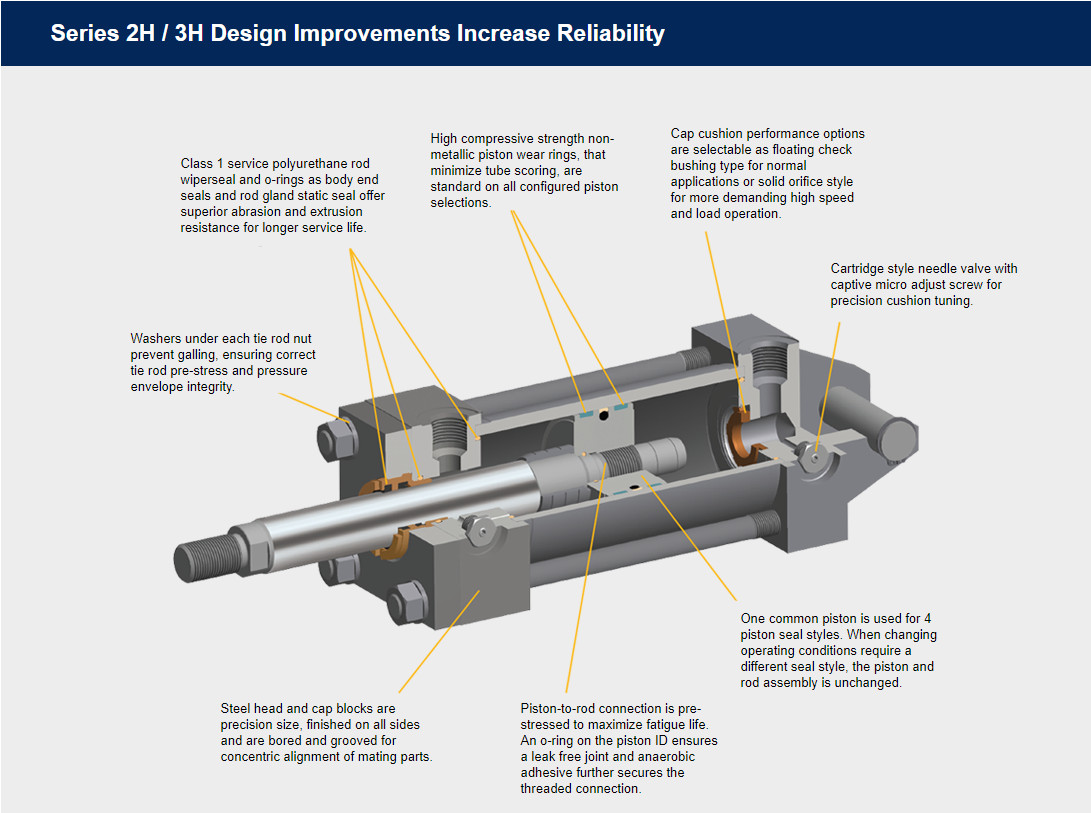

Tie rod cylinders are the most widely used design in all of fluid power. Nfpa tie rod cylinders which are used in the majority of industrial systems can usually be mounted using a variety of standard mating configurations from trunnion style heads and caps to extended tie rod cap and or head end styles flange style heads side lug and side tapped styles a range of spherical bearing configurations and cap fixed. Hydraulic cylinders parts hydraulic components. The piston has sliding rings and seals.

Hydraulic cylinders get their power from pressurized hydraulic fluid which is typically oil the hydraulic cylinder consists of a cylinder barrel in which a piston connected to a piston rod moves back and forth. Reversing the flow of oil through the cylinder retracts the cylinder rod. Tie rod hydraulic cylinder bolt 76 results bolt requirements. End caps hydraulic cylinder component parts medium duty 28 00 173 00.

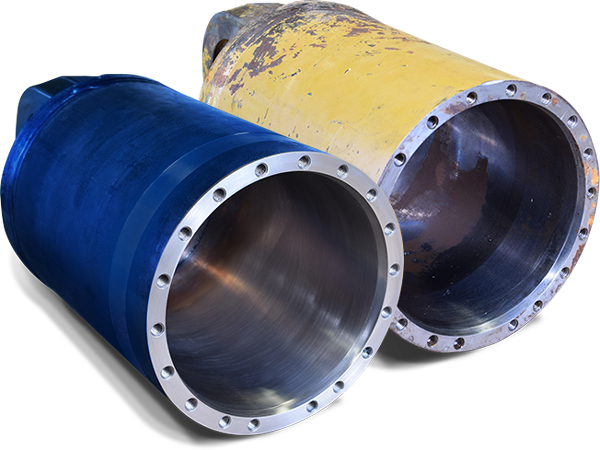

2500 psi heavy duty universal mountings piston rods are sized to operate under full pressure without danger of buckling through strokes of 8 16 inches. An alternative method of manufacture rolls the tube into a slot on the end caps to mechanically lock the three pieces together. Industrial and mobile hydraulics and pneumatics. Another alternative design has the end cap welded to the barrel and a rod end cap secured via threads or a lock ring.

The hydraulic cylinder consists of a cylinder barrel in which a piston connected to a piston rod moves back and forth.