Ionized Air Knife Systems

Exair s gen4 super ion air knife removes static electricity from plastics webs sheet stock and other product surfaces where tearing jamming or hazardous shocks are a problem.

Ionized air knife systems. Air knives air knife systems centrifugal blowers ionized air sytems custom engineering for drying rinsing solutions air knife and air knife systems 1 805 654 7000. Welcome to air knife systems air knife systems designs and manufactures high performance blowers air knives and complete blow off systems for many applications. How it works. How the standard air blade ionizer works.

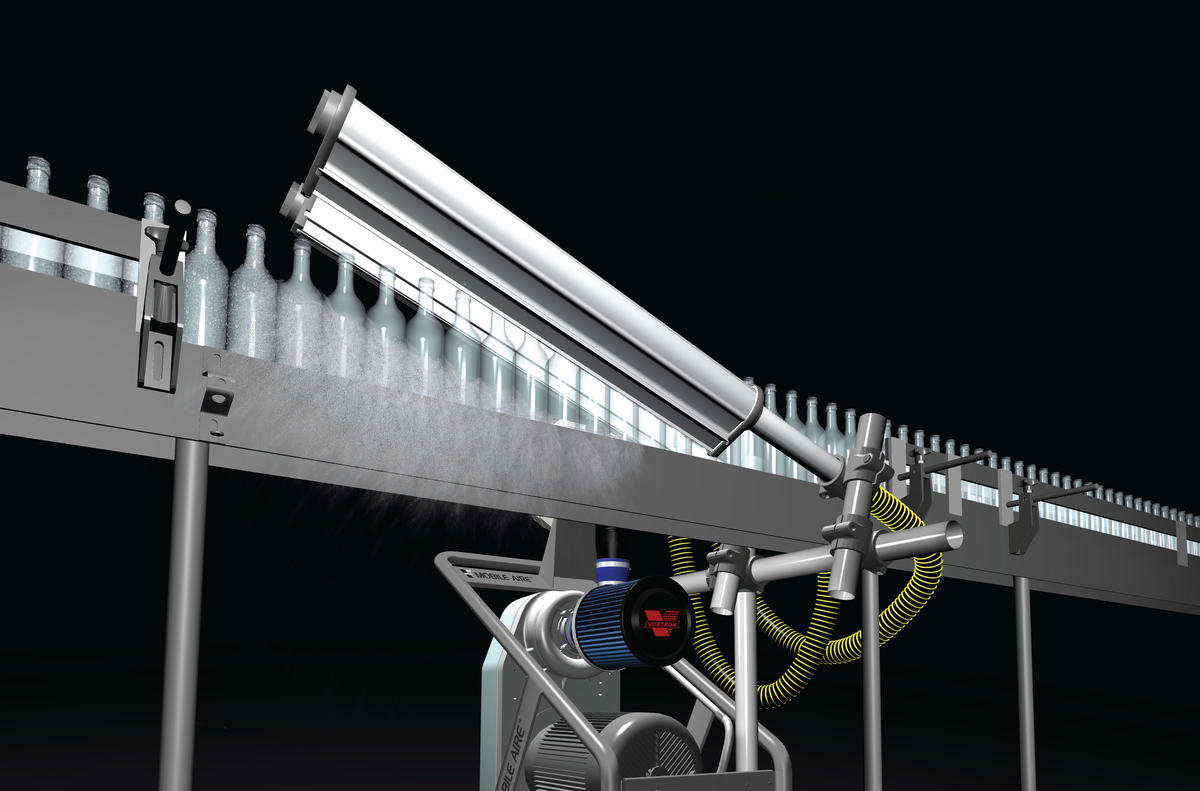

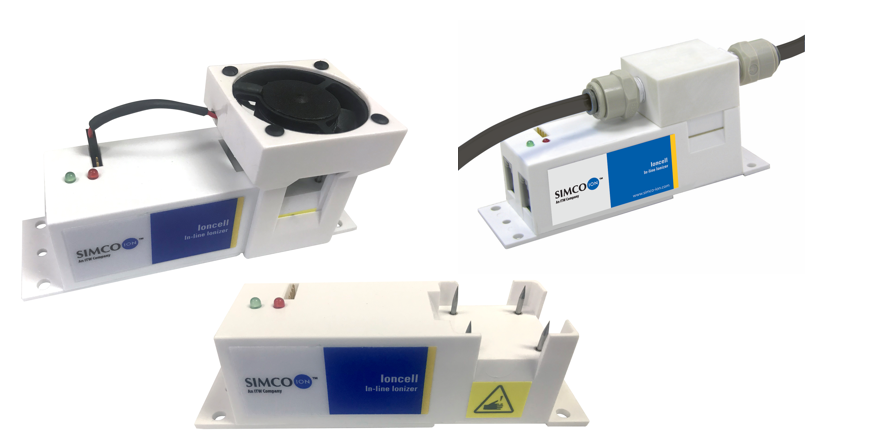

Clean powerful blasts of ionized air eliminate static charge and evacuate particulate from the insides of containers ensuring they are ready for filling. Emitter points are contained within the manifold or knife to promote durability safety and a consistently clean ionizing bar. Aci s range of static elimination systems are a very versatile solution to control or remove static electricity from plastic paper glass and other non conductive materials. For the paxton air system a 5 hp blower will supply three 6 air knives providing 200 cfm air at 60 of water column.

Although our air knife systems are frequently used in the application of removing surface water and liquids they can also be applied to products and processes that involve the neutralisation of static charges. The paxton system will use only 3 3 hp compared to 22 8 hp for the existing compressed air system resulting in an energy savings of about 1 50 per hour and yielding an roi of less than 11 months for a 24 x 5 day operation. Ion3 is powered by the combination of jetair s efficient blowers hepa grade air filtration precision engineered jetblast nozzles and ionizing technology. Air delivery devices are available in lengths from 12 to 10 0 3 3m more active emitter points give increased ionization performance.

Sonic air systems has mastered these air washing systems with the same modular air knife tunnels having static neutralizing ionized blow off complete dust containment and exhaust air blowers with bag filter collection. An integrated debris capture and vacuum system collects and evacuates. Drying of bottles and containers before and after filling.