Liquid Liquid Extraction Equipment Design

Liquid liquid extraction equipment jack d.

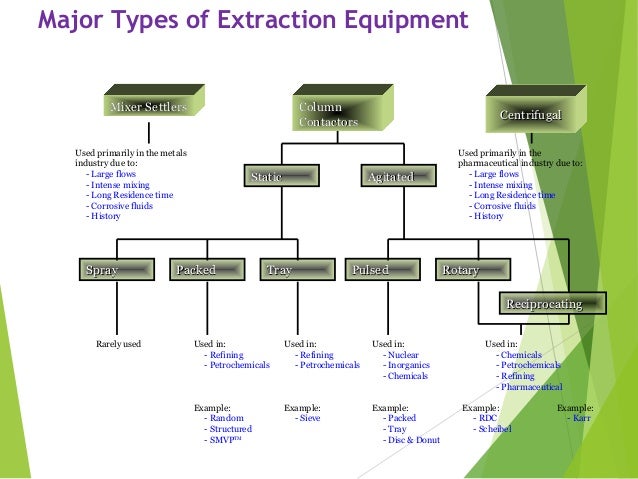

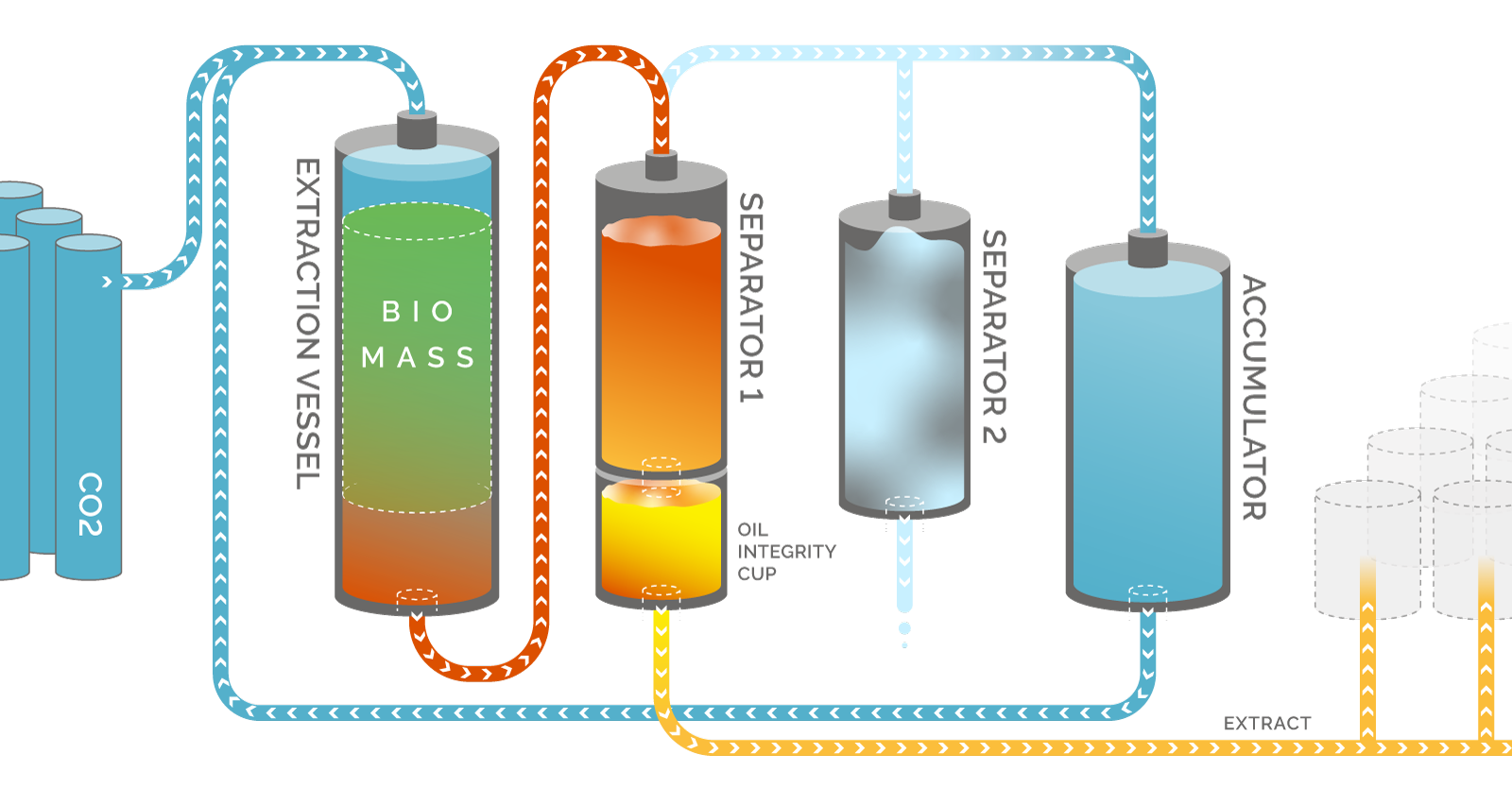

Liquid liquid extraction equipment design. Therefore results from extraction trials with your real feed liquors are important for a reliable process design. Stability of jets in liquid liquid systems. In recent years the use of liquid liquid extraction equipmenthas attracted widespread interest from all major chemicalengineering petroleum and pharmaceutical companies as well asuniversity based scientists and engineers. The liquid liquid extraction process is favorable for separations as for.

It has since been utilized in numerous applications including. Depending on the kind of the second phase this process is named either solid liquid extraction or liquid. This article discusses the basics of liquid liquid extraction and provides guidance on how to select the appropriate solvent and extraction equipment. Fields of application liquid liquid extraction is a complex sepa ration process.

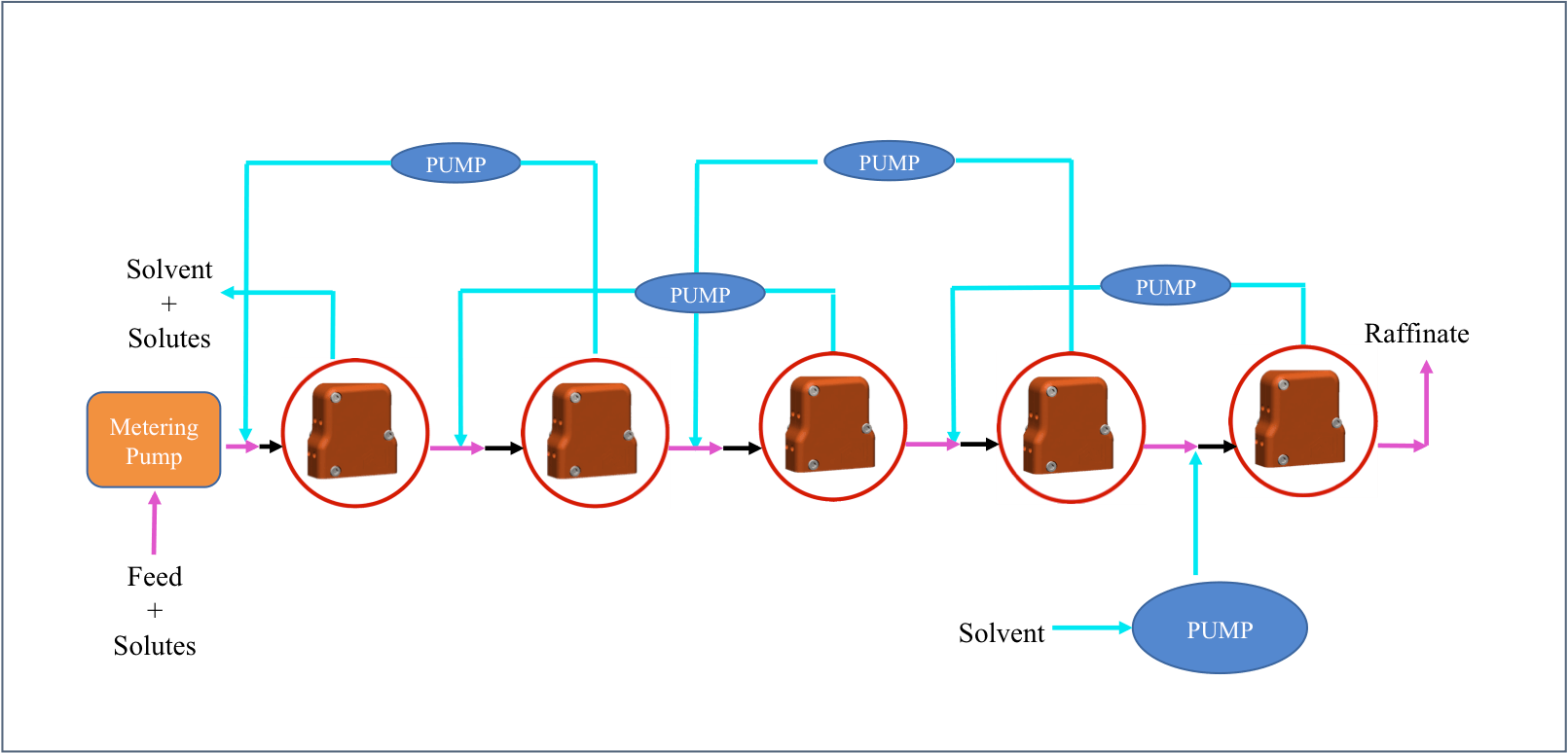

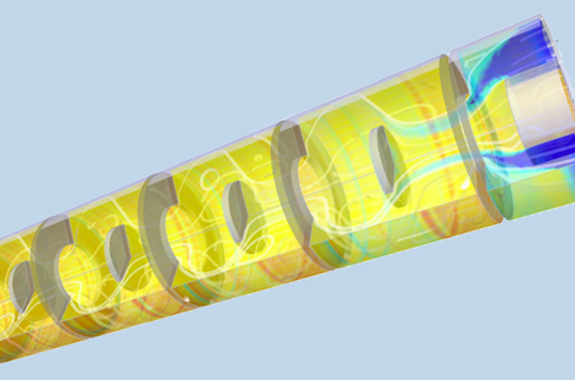

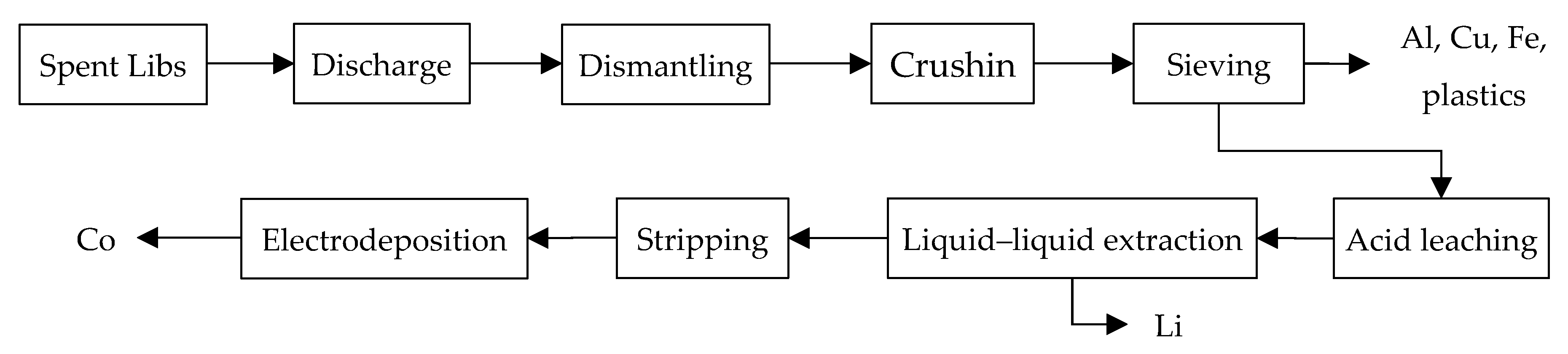

Koch modular process system s extraction technology group has decades of experience designing and supplying liquid liquid extraction lle equipment our liquid liquid extraction columns are engineered to fulfill the challenging purification requirements that exist in the flavor fragrance pharmaceutical biotech petrochemical and chemical industries. Liquid liquid extraction lle also known as solvent extraction and partitioning is a method to separate compounds or metal complexes based on their relative solubilities in two different immiscible liquids usually water polar and an organic solvent non polar. Liquid liquid extraction also called solvent extraction was initially utilized in the petroleum industry beginning in the 1930 s. This requires specially adapted equipment and in depth know how about two phase liquid flows.

An additional component has to be introduced as extractant which makes other subsequent separation steps necessary. There is a net transfer of one or more species from one liquid into another liquid phase generally from aqueous to organic. Possible alternative to distillation. Extraction is typically chosen over distillation for separation applications that would not be cost effective or even possible with distillation.

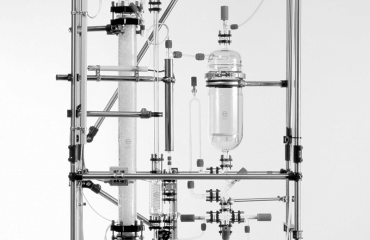

Solvent extraction and ion exchange 1984 2 3 323 352. Borosilicate glass 3 3 is an ideal material for extraction equipment as the process can be optimized while visually observing the process. These extraction plants are built by de dietrich process systems from the most appropriate. Yoshiro kitamura hiroyuki mishima teruo takahashi.

Law and terry a. Liquid liquidextraction equipment presents.