Liquid Liquid Extraction Equipment Ppt

Thus extraction can be performed at low temperatures.

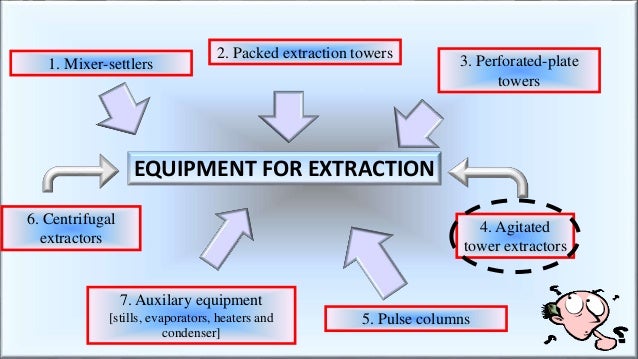

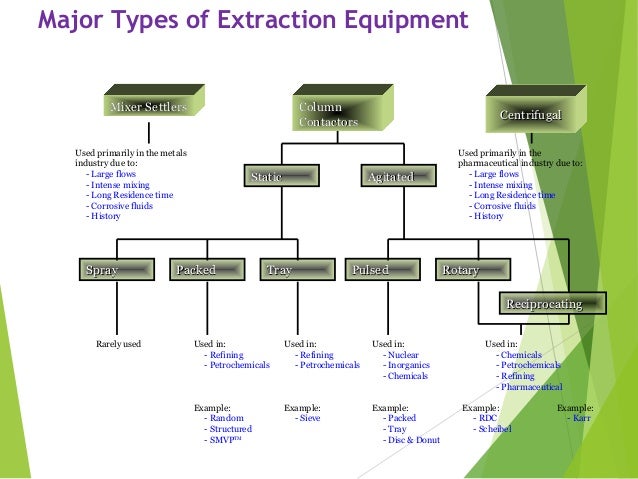

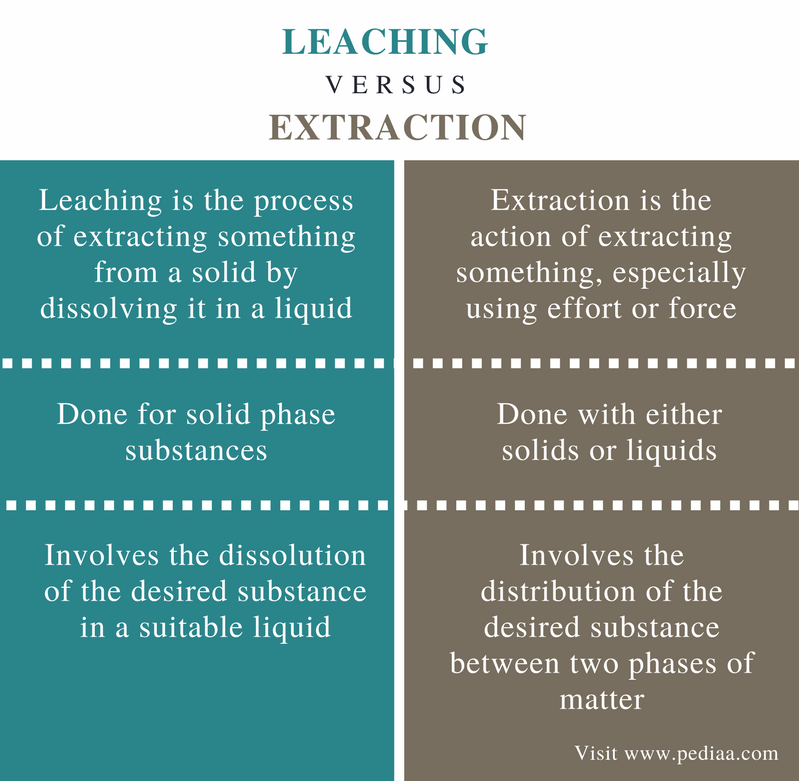

Liquid liquid extraction equipment ppt. Contacting solvent and solid to effect a transfer of a solute leaching. Law and terry a. Factors influencing the rate of. Types of equipment and design for liquid liquid extraction 12 6a.

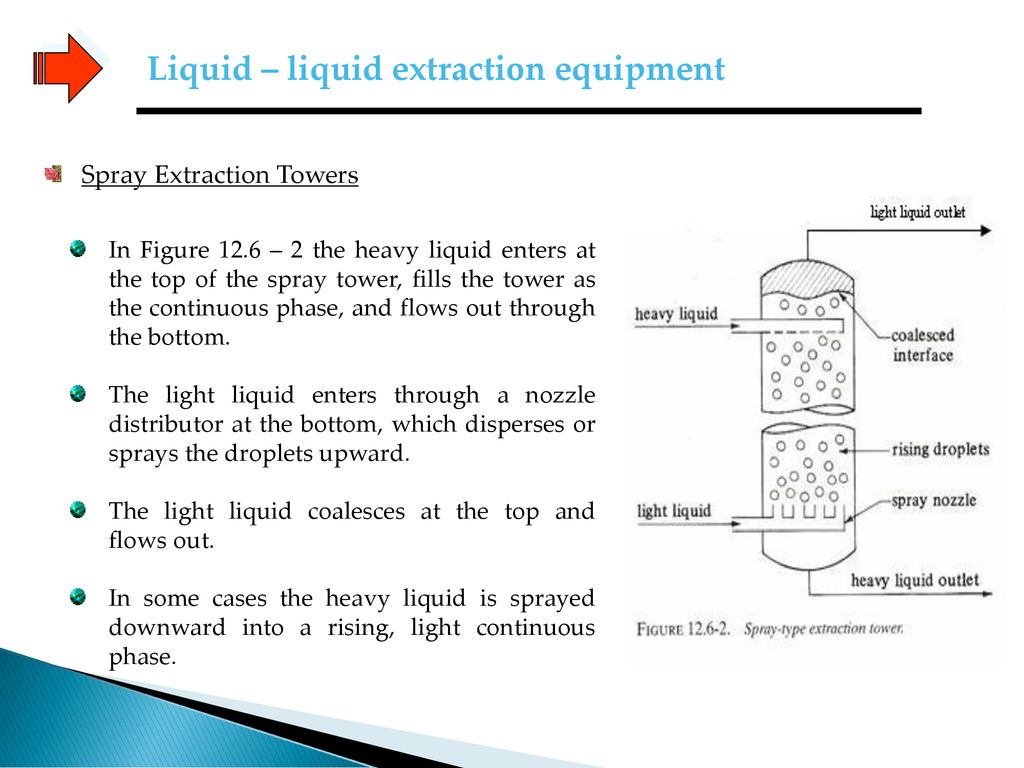

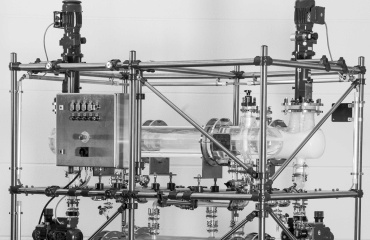

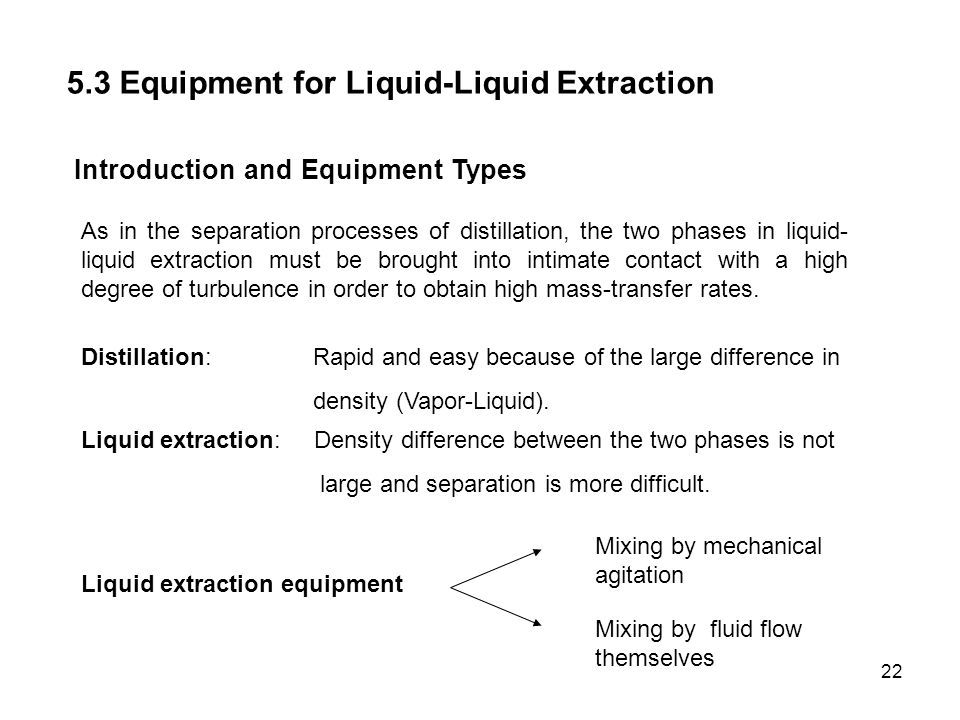

Liquid liquid extraction experiment 350 ech4404l. Introduction and equipment types. As in the separation processes of absorption and distillation the two phases in liquid liquid extraction must be brought into intimate contact with a high degree of turbulence in order to obtain high mass transfer rates. Solvent recovery economics viscosities interfacial tension solids product solvent value flowrates risk assessment operation experience static columns a spray tower packed tower static columns light liquid out.

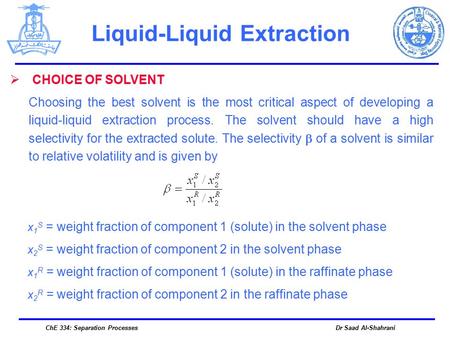

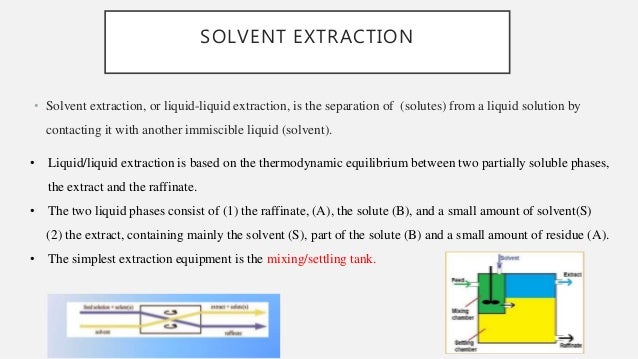

Liquid liquid extraction also known as solvent extraction is a method to separate compounds based on their relative solubilities in two different immiscible liquids usually water and an organic solvent. Packed extractor design hydraulics packed extractor design mass transfer extraction equipment selection depends on. Todd idaho national laboratory. The equilibrium data for a liquid liquid system are of vital importance in the selection and design of an extraction equipment.

It is an extraction of a substance from one liquid phase into another liquid phase. It has since been utilized in numerous applications including. Solid liquid extraction leaching leaching. Unit operations lab ii.

Liquid liquid extraction also called solvent extraction was initially utilized in the petroleum industry beginning in the 1930 s. Liquid liquid extraction equipment jack d. There is a net transfer of one or more species from one liquid into another liquid phase generally from aqueous to organic. Periodical extraction is the process in which separatory funnel which contain substance which extragent is shaked continuous extraction countercurrent extraction.

The separation of the solution from the remaining solid washing. Leaching occurs in two steps. Liquid liquid extraction lle also known as solvent extraction and partitioning is a method to separate compounds or metal complexes based on their relative solubilities in two different immiscible liquids usually water polar and an organic solvent non polar. Liquid liquid extraction with solvents more dense than water.

Extraction is a process where one or more solute s are removed from one liquid phase technically called a diluent by transferring that those the solute s to another liquid phase or a solvent since this is the operation between the two liquid phases no vaporisation is needed. The organic mixture is fed counter current to the extraction solvent water. The most common method of liquid liquid extraction is performed using a separatory funnel.